Pretty busy week, as I’m trying to get ready for five weeks of racing on the road.

Screamin’ Woody

Started with an oil change, as the car was initially jetted way too rich at the race in Martin, and there was a little odor of gas in the oil. I cut the oil filter open and found a little silver from the ill fitting Jessels Indy (back in the Russ Flagle days) installed. Long story short, despite my telling Kenny I wanted TD Machine Rockers when they (poorly!) built this engine, they put Jessels on. Even with lash caps, the geometry sucked and I kept eating up rockers on #7 Intake. I changed to TD Machine in early July, and pretty sure that problem is solved. Back to the filter, I saw some small silver flakes from the rocker slipping off the pushrod and getting its underside beat up. However, I saw no gold – thankfully. I have great oil pressure of 70psi cold at idle. Also did an under-hood nut and bolt check. All was well.

While on the rack, I did an under-car nut and bolt check, and found all of the nuts holding the chunk to the 9″ rear-end housing were loose. A couple of them were 720 degrees loose. Everything else was tight.

After making sure everything was tight, and adding a pint to the rear-end, I turned the Shop Rat loose to scrape the crud off the read-end, rubber crumbles out of the tubs, and to spray and wipe the underside clean.

I had an oil leak coming from under the intake manifold while racing in Martin, MI. I stuffed some blue paper shop towels under the front and back of the intake and that got me through the race dripless. However, now was the time to fix it right and remove the intake to see exactly where the leak was.

It turns out a valley pan inspection cover plate had a 1/4″ bolt walk off. I’d also slightly overtightened by getting lazy and using a battery wrench when I’d tightened in June – searching (and finding) a pushrod tip the shitty Jessel geometry had broke off. The soft aluminum plate had been on and off many times and developing a little warp in many of the bolt holes. I cleaned it and the gasket and flipped over before bolting down with a 1/4″ ratchet – to ensure not over tightened. Once bolted on, I smeared on a thin coating of Ultra black with my finger – as I don’t want to have to take off the intake again this year. I’ll order a new plate and gasket and replace them over the winter.

While the 15-year old and very greasy intake was off, I removed the Carbs, scraped the old Permatex off base and lid, cleaned the intake with Braklean, washed with soapy water and brush, rinsed, blew dry with compressed air, taped off and hit with a can Grey primer. After the primer had dried, I hit with the intake with a couple coats of the same gloss black I used on the valve covers – and then let it dry in the hot Texas sun for a day.

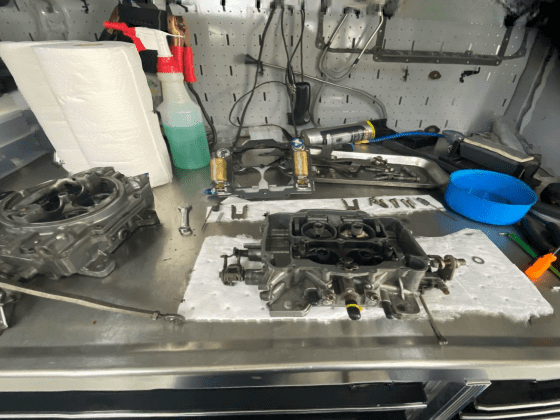

While that was drying, I re-jetted the carbs. For ten years, I’ve always moved between 113 Square, 113/110 and 110 square. There’d never been a jet smaller than 110 in any of my cars. At Martin, I was 113 square and the weather was horrible. It was a hot muggy swamp. The water grains was 130 (30 sux and 130 is pretty rare) with the Temperature near 100. My car ran like shit, and got slower with each pass. Checking the evac oil it smelled like gas, and a plug pulled was sooty black. The consensus among friends was to replace the rear jets with 104s. I did that and it picked up 8 numbers.

Back at the shop, I’ve received a ton of advice from people who are pretty damn smart, and who I trust – but none of it was the same. I finally went with the advice of the guy who knew this engine best (he fixed all of the Indy screwups) and modified my carbs. It also was what I strongly felt. So while it is fatter than all of the other suggestions – I went 110/107 as a starting point. I’ll adjust from there based on how the car runs, feels, and spark plug looks.

I also cleaned them up a little, sprayed a little WD40 on the linkage and any corrosion, and wiped off. I put the intake and carbs back on and hooked up all lines and cable. I let the Permatex dry over night and fired the car up yesterday – looking for leaks. It sounds pretty good.

I still need to check for WOT, adjust the idle, and change spark plugs to next hotter before loading up for next races.

Texas Thug

I have a pretty bad transmission leak coming out of the bellhousing. I suspect, front seal, and/or pump gasket, and/or pump bolt washer/seals. So I pulled off the belly pan that was containing it and put the car on Jack-stands. I have a lift and transmission jack, but the guy I hired to take the lead (I’ll assist) doesn’t like lifts and wants to do on the floor.

That happens next week. When we’re done with that, I’ll do a nut and bolt check on it and put the belly pan back on.

Seadoo Trailer

Yesterday I left the shop for a week at my little cabin on the lake. I’d been living in the motorhome for a month, needed a little R&R, and have a lot to do up here. That said, I came down with the bug yesterday afternoon and trying to just take it easy until I feel better. However, one important task I must do is to start my two Seadoos, which haven’t been started in 2 years – and bring them back to the shop to clean up a sell. We never use them and they’re fetching top dollar right now. My double Seadoo trailer has been setting in back of the shop for over three years in the sun. That had the bunks pretty much turned to trash So I ordered some bunk carpet, bought a pair of 12′ treated 2x4s and new stainless steel hardware. I also had to make a new bunk bracket that had rusted away. All cleaned now and made the 100 mile trip to the lake

Finally

To keep the shop rat busy whilst I be at the lake, I shagged up a couple of yards of black mulch for him to pitch into the Oleander bed that runs the length of the Motorhome Port. Naturally, after he weeds and rakes the existing mulch,

Next

I return to the shop next Friday to mow 5 acres, R&R (fix) transmission on Thug, the previously mentioned nut & bolt check; clean up the Seadoos and list for sale; fabricate a which pulley for the stacker; clean up and photo/list for sale two sets of rockers (one for a 440-1 and one for 572-13); clean off a work bench and 5 carts of parts that need to be cleaned, wrapped and put away in storage containers; organize the inside of stacker; and load up both cars and golf cart into the stacker. I also have to service the Coach’s generator – with 1300+ hours and 9 months since last Serviced.

5 Weeks On The Road!

On the 23rd, we leave to drive to the Norwalk, OH’s race. From there, we’ll go to my wife’s Ancestral Stomping Grounds in WNY for two weeks. From there we go to the Moparty race in Bowling Green, and finally we head to the Dave Duell Classic in Indy. After that, my 2021 racing season is over – although I might try to make a regional race if there is one. Over the winter there is a lot to do with both cars to prepare for 2022 – but that’s for a later discussion.